Our Strength

We are pioneers in sustainable industrial solutions, driven by a mission to merge cutting-edge technology with environmental responsibility. Born from a passion for innovation and a commitment to the planet, our company redefines efficiency by offering high-performance, eco-conscious materials that empower businesses to thrive—without compromising the future.

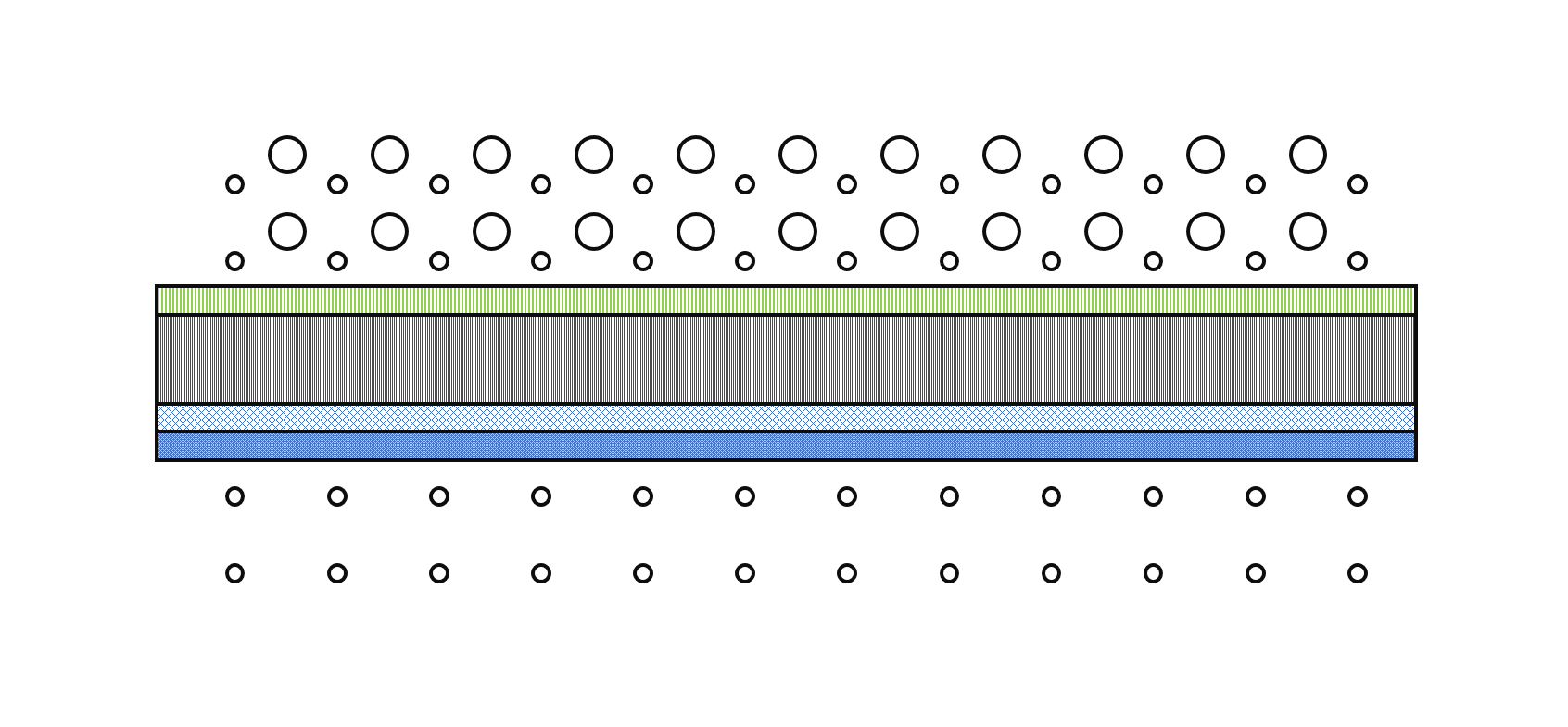

Eco-Friendly Filtration Film

| High-efficiency filtration for air and liquid applications | |

| Reduce harmful chemicals from entering the atmosphere and water source | |

| Made with recyclable materials, reducing waste and energy consumption |